AI for Inventory Management in F&B: Success stories and future trends

Discover how AI for inventory management helps F&B businesses predict demand, cut waste, and boost efficiency for sustainable, data-driven growth.

Managing inventory in the food and beverage (F&B) sector has never been simple. Every day, businesses must accurately predict how much to order, keep ingredients fresh, and avoid excess stockpiling up in storage. When demand shifts quickly, even a slight forecasting error can result in waste or lost sales.

To stay competitive, modern F&B companies are turning to AI — a technology that brings data-driven precision into everyday inventory decisions. Instead of relying on gut feelings or outdated reports, AI for inventory management transforms real-time data into reliable insights — helping teams adjust more quickly, minimize losses, and serve customers better.

In this article, we’ll look at:

- What is AI for inventory management?

- Key benefits of applying AI in Food Inventory Management

- Success examples of AI in F&B Inventory Management implementation

- Future Trends in AI for F&B Inventory Management

- AI for inventory management: for the food industry

I. What is AI for Inventory Management?

First, you can explore about the overview of ERP for Food Industry: Benefits, challenges and who should use it here.

Many businesses have faced the same frustration — stock running out just as demand peaks, or excess goods taking up valuable storage space. That’s where AI for inventory management comes in, helping companies move from reactive decisions to proactive control.

AI for inventory management isn’t about robots taking over the warehouse. It’s about using more innovative tools that learn from what’s already happening in your business — such as sales data, seasonal patterns, and delivery timelines — and turning that into useful predictions.

Instead of scrolling through spreadsheets or manually checking stock, managers can view updates in real-time. The system spots when products are moving faster than usual, gives early warnings when items might run out, and even recommends reorder points. Some companies plug in IoT sensors to track every movement in and out, ensuring the data remains up-to-date at all times.

It doesn’t take long to see the benefits: fewer shortages, fewer piles of unsold goods, and less guesswork. Teams spend less time counting and more time planning. Customers notice that too — when what they want is always available.

Analysts say this shift is already reshaping the industry. The market for AI-driven inventory tools is expected to surge from approximately $9.6 billion in 2025 to over $27 billion by 2029 — representing nearly 30% annual growth. So yes, AI may sound like a buzzword, but getting started now still puts your business ahead of most.

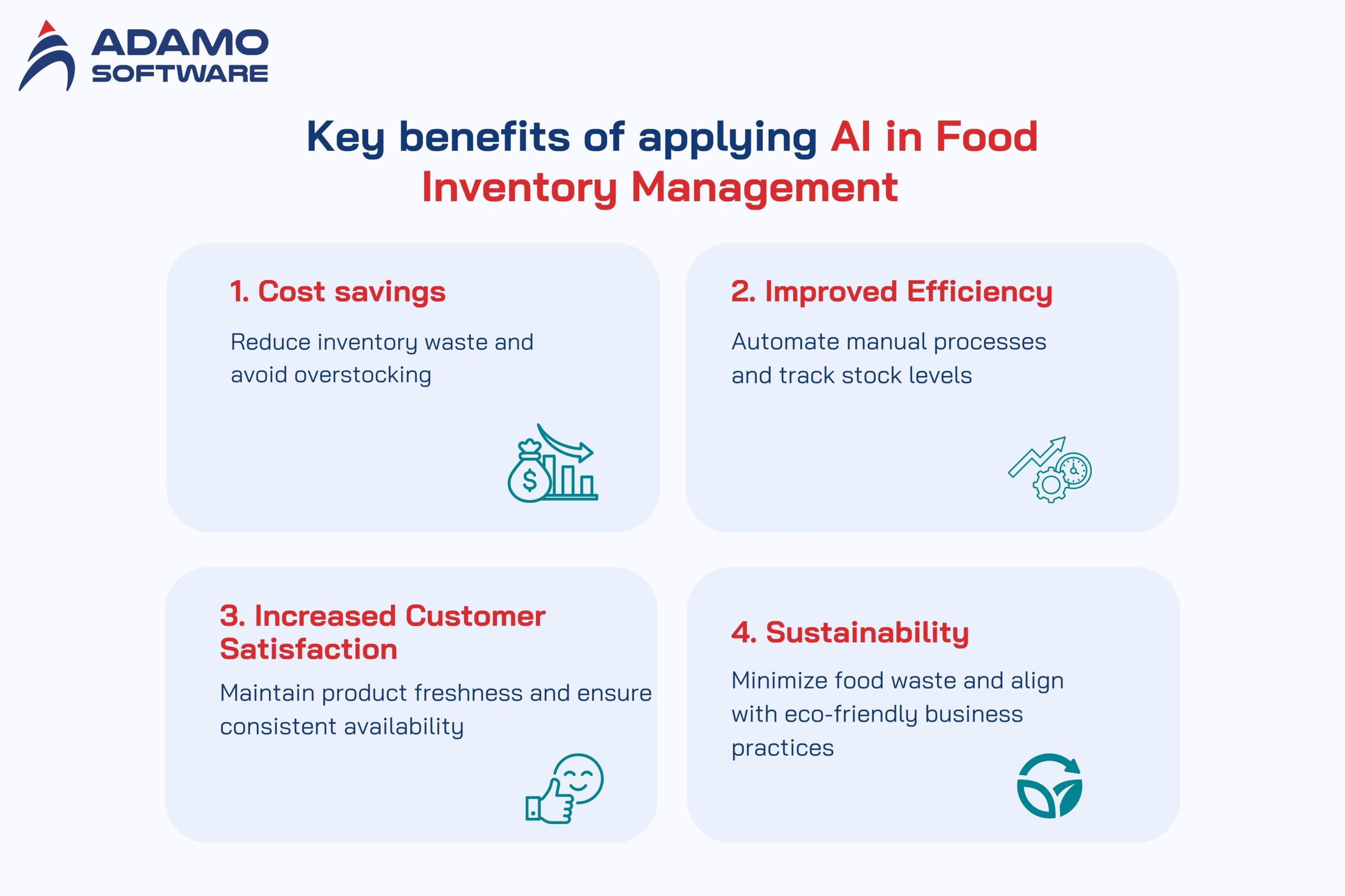

II. Key benefits of applying AI in Food Inventory Management

AI for inventory management brings measurable benefits that go far beyond automation. It improves cost control, operational efficiency, customer experience, and even supports sustainability goals. Below are the key advantages every F&B business can gain:

- Cost Savings: Reduce inventory waste and avoid overstocking to save costs.

- Improved Efficiency: Automate manual processes and track stock levels in real time.

- Increased Customer Satisfaction: Maintain product freshness and ensure consistent availability.

- Sustainability: Minimize food waste and align with eco-friendly business practices.

1. Cost Savings

Inventory waste is one of the most significant hidden costs in the food and beverage (F&B) industry. With AI-driven forecasting, businesses can finally gain better control over what gets ordered and when.

Instead of relying on intuition or past habits, AI for inventory management analyzes real sales data, seasonality, and external factors like holidays or weather trends to fine-tune purchasing plans. The outcome is less spoilage, fewer stockouts, and more substantial cash flow — a simple shift that directly impacts the bottom line.

2. Improved Efficiency

Manual tracking often leads to delays and human errors, especially when managing multiple outlets. AI for inventory management eliminates that complexity.

By automating stock monitoring, updating inventory in real time, and generating low-stock alerts, teams no longer need to spend hours reconciling reports. Operations become more synchronized between suppliers, kitchens, and storage, freeing managers to focus on service quality and team performance instead of paperwork.

3. Higher Customer Satisfaction

Customers might never see your inventory system, but they certainly feel its effects.

AI for inventory management ensures that high-demand products are always available, and that freshness is never compromised. For F&B brands, this reliability fosters trust and consistency — two key factors that significantly influence customer loyalty and repeat business.

4. Sustainability and Waste Reduction

Food waste reduction is no longer just an operational goal — it’s a sustainability commitment.

With AI-powered demand forecasting, businesses can order more intelligently, reduce excess inventory, and minimize their environmental impact. Beyond cost savings, this shift also reflects positively on brand reputation, showing consumers that the business values both efficiency and responsibility.

Altogether, AI helps F&B brands save costs, streamline workflows, and create a more sustainable operation that customers can trust.

Explore Our Tailor-made Software Development Solutions

We are confident in providing end-to-end software development services from fully-functioned prototype to design, MVP development and deployment.

III. Success examples of AI in F&B Inventory Management implementation

Real-world success stories prove how AI for inventory management is transforming daily operations across the F&B sector. For instance, Dishoom is one of those brands that really shows what data can do when used right. They applied AI for inventory management to analyze daily ingredient usage and adjust supply accordingly. Within months, food waste dropped by around 20%. It’s not just about saving money — it’s about building a more sustainable kitchen that runs efficiently every single day.

McDonald’s: Bringing AI forecasting to thousands of outlets

McDonald’s approach to AI is all about scale. Their system gathers sales data from restaurants worldwide and turns it into actionable insights for distribution and planning. It helps each outlet stay stocked without over-ordering. What’s impressive is how seamlessly AI integrates into a massive, complex supply chain — proving that even global operations can run more smoothly with the right technology.

Inventory Inquiries Cut by 27%, Freeing Up Management Time

Many restaurant operators report fewer questions about inventory once AI for inventory management is in place. The average drop is around 25–27%. Managers no longer have to chase reports or double-check stock levels as frequently. The time saved is reinvested in improving the customer experience, staff training, or simply running things more smoothly during peak hours.

ROI in under a year — and long-term benefits after

What’s most encouraging is how quickly these systems pay off. Most F&B businesses see clear returns within 6 to 12 months of implementation. Between reduced waste, improved ordering decisions, and smoother operations, the cost of implementing AI for inventory management often balances faster than expected. More importantly, it sets up restaurants for long-term control and resilience in a fast-changing market.

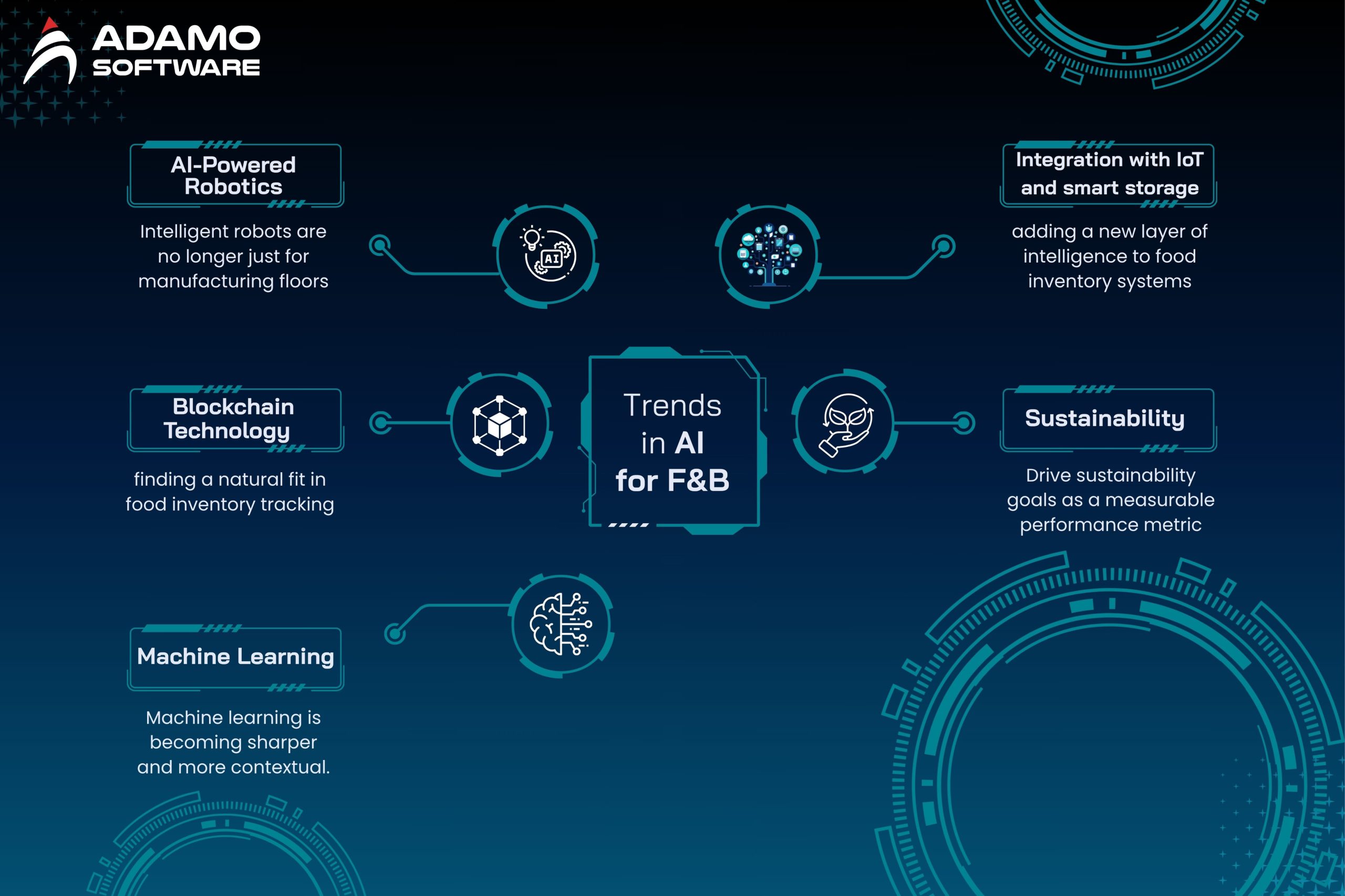

IV. Future trends in AI for F&B Inventory Management

The future of AI for inventory management is shaping up to be more intelligent, connected, and sustainable than ever. As technology evolves, restaurants and food brands are moving beyond prediction — they’re building systems that can think, act, and adapt in real time.

1. AI-Powered Robotics

Intelligent robots are no longer just for manufacturing floors. In modern kitchens and warehouses, AI-driven robots are increasingly handling repetitive tasks such as restocking shelves, sorting ingredients, and picking orders. The result? Fewer manual errors, faster turnaround, and a more reliable flow from storage to service.

2. Blockchain Technology

Blockchain technology is finding a natural fit in food inventory tracking. By creating tamper-proof records of every step — from farm to plate — it strengthens food safety and product authenticity. For F&B businesses, this means real-time traceability, improved compliance, and increased consumer trust, particularly in export and premium markets.

3. Machine Learning

Machine learning is becoming sharper and more contextual. Instead of just forecasting based on past sales, future AI for inventory management will incorporate external data — including weather, local events, and even social trends — to fine-tune purchasing and production plans. This allows restaurants to prepare for fluctuations before they happen, cutting both waste and missed sales.

4. Integration with IoT and smart storage

The Internet of Things (IoT) is adding a new layer of intelligence to food inventory systems. Sensors placed in refrigerators, shelves, or delivery boxes continuously update temperature, humidity, and stock levels. When combined with AI for inventory management, these insights help maintain food quality and automate replenishment with little human input.

5. Sustainability as a business advantage

AI for inventory management will continue to drive sustainability goals — not as a side benefit, but as a measurable performance metric. More innovative inventory planning results in fewer expired items, optimized energy use, and a reduced carbon footprint. For modern food and beverage (F&B) brands, sustainability is no longer a trend — it’s a key differentiator in consumer loyalty and brand reputation.

V. Final thoughts

Inventory management has long been one of the most significant challenges in the food and beverage (F&B) industry. How to ensure fresh ingredients, save costs, and still serve customers’ needs? Technology now helps solve most of those problems. With an AI for inventory management, businesses can track inventory in real-time, predict demand more accurately, and minimize waste—all toward a better customer experience.

At Adamo Software, we develop customized software solutions tailored to each business model. Whether you are a restaurant chain, a coffee brand, or an F&B manufacturing enterprise, Adamo’s team of food and beverage software experts is always ready to help you optimize your operations and increase long-term efficiency.

Ready to take control of your F&B inventory? Contact us to discover how Adamo can help you manage your inventory more effectively and grow sustainably in the competitive food and beverage market.

FAQs

1. What are the common challenges in food inventory management?

The most frequent issues include inaccurate stock data, high levels of waste, inconsistent supply, poor demand forecasting, and financial losses. These challenges can quickly affect both operations and profitability.

2. What inventory rotation methods do food inventory systems support?

Most tools follow FIFO (First-In, First-Out) or FEFO (First-Expired, First-Out) principles. They ensure older ingredients are used first — keeping food fresh and minimizing waste.

3. How does food and beverage inventory software help maintain product quality?

It tracks stock levels, monitors expiration dates, and ensures consistent ingredient sourcing. This helps maintain product freshness and consistent quality across all outlets

4. Can the system send alerts for low stock or products nearing expiry?

Yes. AI-powered platforms allow you to set alert levels for low stock or near-expiry items. This feature helps reduce waste, avoid shortages, and ensure product freshness

5. Is food inventory software suitable for multi-location operations?

Absolutely. Most modern systems are cloud-based, offering real-time updates across all branches. You can easily track stock levels and make purchasing decisions from anywhere

6. What should I consider when choosing an inventory management solution?

Choose a platform that fits your team size, workflow, and budget. Focus on features that address your specific pain points — not just the ones that sound advanced. The right choice helps simplify operations and cut unnecessary costs.