ERP Software for Food Industry: Benefits, challenges and who should use it

Discover how ERP software for food industry helps boost efficiency, reduce waste, and improve planning for growing food businesses.

ERP systems now serve as a critical foundation for running modern food and beverage businesses. This is especially true now that supply chains are moving faster, margins are getting tighter, and safety rules are continuing to get tougher.

As companies search for better control and coordination in everything they do, the role of ERP continues to grow. In this article, we’ll discover a couple of fundamental themes that guide how food businesses function and expand:

- Importance of ERP software for food industry

- Benefits of food ERP software

- 5 key implementation challenges with food and beverage ERP software (solutions included)

- Food businesses that can take advantage of ERP software

I. Importance of ERP Software for food industry

Food and beverage businesses deal with constant operational challenges, from monitoring every expense to managing raw materials and inventory. ERP software for food industry operations comes in as the system that brings all of these moving parts together.

It is like the central brain of the business, linking important functions and helping the team manage everything with greater clarity and efficiency. These are the main factors that make adopting an ERP system vital for food and beverage businesses today:

- Stronger inventory oversight

- Smarter production coordination

- Reliable product and ingredient traceability

- Clearer recipe costing and performance tracking

- Improved customer experience

- Streamlined operational workflows

1. Increased oversight of inventory

ERP software for food industry operations provides real-time monitoring of raw materials, work in progress, and finished goods. This helps businesses avoid shortages, prevent excess waste, and improve purchasing accuracy.

2. Better production coordination

By connecting production timelines to inventory data, ERP software for food industry workflows enables better food preparation, as well as more efficient ingredient usage. This enables companies to meet demand with reduced delays.

3. Traceability of reliable product and ingredients

Food businesses need to adhere to strict safety regulations. ERP for food industry compliance helps accurately track ingredients, processing steps, and expiration dates. This ensures the team stays aligned with legal and quality standards.

4. Better recipe costing and performance tracking

ERP software for food industry management estimates the cost of recipes with precision and updates the revenue data in real time. This allows businesses to have a better understanding of how menus are performing and can inform well-thought-out pricing or recipe changes.

5. Improved customer experience

When ERP software for food industry solutions is integrated into point-of-sale systems, businesses can get a better insight into their customers. This enables them to fine-tune service and respond better to customer requirements.

6. Streamlined working processes

ERP software for food industry operations includes modules for logistics, chain store management, scheduling, and other core functions. These tools help to reduce manual work while keeping the processes consistent and reducing the cost of operations.

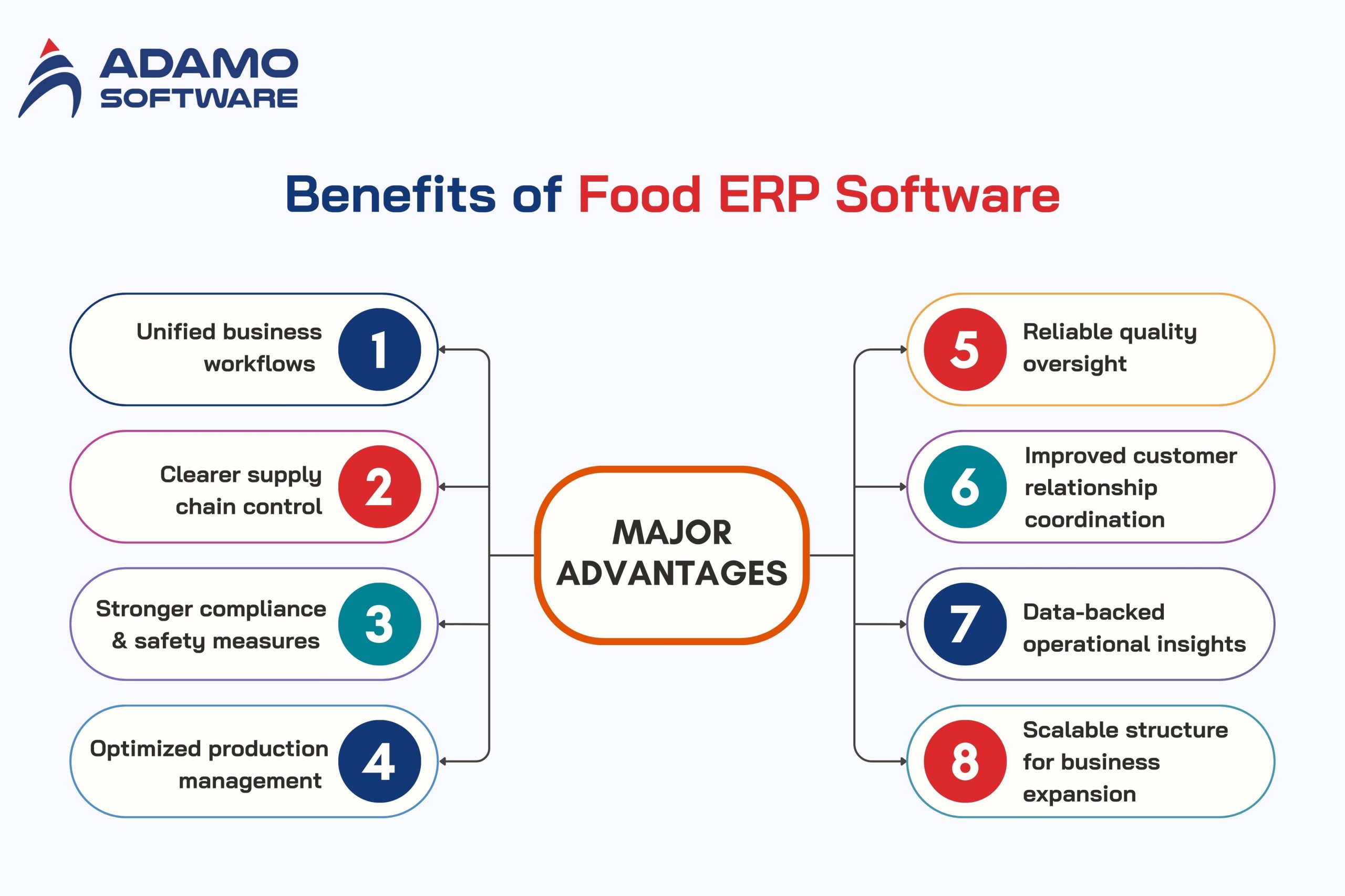

II. Benefits of food ERP software

As operations scale, teams need tools that will help them stay coordinated, keep data accurate, and react quickly to changes in demand.

ERP software for food industry workflow provides businesses with that foundation by strengthening every stage of production and management. Below are the key focus areas that are supported by food ERP systems:

- Unified business workflows

- Clearer supply chain control

- Stronger compliance and safety measures

- Optimized production management

- Reliable quality oversight

- Improved customer relationship coordination

- Data-backed operational insights

- Scalable structure for business expansion

1. Unified business workflows

ERP software for food industry operations connects all aspects of procurement, production, inventory and distribution into one connected system. Real-time updates help in reducing manual work, reducing errors, and facilitating faster coordination between departments. This results in smooth-running operations and more efficient use of resources.

You can explore more about Inventory Management System: Ultimate Guide for F&B Business here.

2. Improved control over the supply chain

The nature of perishable goods calls for precision monitoring. ERP software for supply chains in the food industry monitors the level of stocks, expiry date, and batch number in real time. This helps maintain ideal inventory levels, reduces waste, and facilitates timely delivery. It is also used to better coordinate suppliers with improved planning and order tracking.

3. Increased compliance and safety measures

Food companies have to comply with strict regulations in every process. ERP software for food industry compliance is used to support such standards as HACCP, FDA, and ISO. It allows for complete ingredient and product traceability, more timely resolution of issues, and in-depth reporting for audits. Quality control work can also be tracked and automated.

4. Optimized production management

ERP software for food industry production planning is used to create efficient production schedules by using demand forecasts, available materials, and capacity data. This approach shortens lead times and reduces costs as well as helps to keep the quality of the product stable.

5. Reliable quality oversight

ERP software for food industry quality control is used to monitor key parameters during production. It takes care of the inspection, tracks deviations, and records quality data in real-time. This is used to help teams correct issues in a short amount of time and maintain the same standards.

6. Better customer relationship coordination

ERP software for food industry customer management incorporates CRM software to monitor the sales orders, customer preferences, and previous interactions. This provides personalized service and helps to build better customer loyalty. Companies can also use CRM data to inform better marketing strategies.

7. Data-based operational insights

ERP software for food industry analytics centralizes real-time data throughout the company. Teams can analyse sales trends, monitor the performance of production, and understand the supply chain behaviour. These insights will help make better decisions and keep companies ahead of market changes.

8. Scalable Structure to Grow Business

As businesses expand, they require systems that have the capacity to adapt to new demands. ERP solutions for food industry are highly scalable and flexible, supporting new product lines, market expansions, and integrations with other systems. This flexibility promotes long-term stability and expansion.

III. 5 key implementation challenges with food and beverage ERP software (solutions included)

Rolling out ERP software for food industry workflows can transform efficiency and compliance, but the road to full adoption isn’t always smooth. Many F&B businesses face similar challenges when setting up and during the early stages of operations. Here are the five big challenges to be on the lookout for:

- Complexity of implementation

- Resistance to organizational change

- Data migration difficulties

- Budget and cost overruns

- Compliance and regulatory barriers

1. Complexity of implementation

Integrating production, procurement, inventory, quality control, and distribution into one central platform can be a strain for teams without prior experience. Misalignment between old workflows and new modules may also slow down progress or cause confusion.

Solution:

Use structured rollout that includes a clear project plan, implement the system in phases, and do pilot runs of the critical system modules. This helps the team to adjust gradually while giving the digital transformation services company room to resolve technical issues early.

You can dive deep into AI for Inventory Management in F&B: Success stories and future trends here.

2. Resistance to organizational change

New ERP software for food industry operations often breaks up established routines, which can cause pushback from employees. Many are afraid of increased workload, loss of control, or the need to learn how to do everyday tasks again. Without the support of the internal team, even the best ERP system can end up being underused or poorly implemented.

Solution:

Create a simple change management plan that explains the benefits and brings employees into the process. Additionally, provide hands-on workshops so that staff feel supported rather than sidelined.

3. Data migration difficulties

Moving old data into a new ERP platform is risky with records from legacy systems, mixed formats, or outdated spreadsheets. Errors, duplicates, and inconsistencies can enter the EPR easily. Once that happens, they can cause reporting, planning, and compliance tracking to be distorted throughout the system.

Solution:

ERP software for food industry operations provides real-time monitoring of raw materials, work in progress, and finished goods. This helps businesses avoid shortages, prevent excess waste, and improve purchasing accuracy.

4. Budget and cost overruns

ERP implementations frequently surpass initial budget, particularly in the event that the companies underestimate the customized needs or run into delays. These unexpected costs may put pressure on resources and slow the project down in the long term.

Solution:

Establish a realistic budget that prioritizes features that are most important and leaves room for surprises. Also, explore cloud-based ERP solutions that can more sustainably spread costs.

5. Compliance and regulatory barriers

F&B companies operate under strict standards for safety, traceability, and record-keeping. As a result, it can be difficult to get an ERP system set up correctly originally. If compliance features are not established correctly, businesses are at risk of holes in oversight and quality control.

Solution:

Work with regulatory specialists to set up compliance related modules properly and select an ERP platform that was built with flexible food safety features. This will help you adapt to changing regulations.

IV. What kind of food businesses benefit from Food ERP?

Different segments of the food industry utilize ERP in their own way, and it integrates into the food industry’s workflows more naturally than people expect. Below are some of the groups that rely on ERP the most:

- F&B manufacturers

- Food distributors and wholesalers

- Retailers and grocery operators

- Food service brands

- Processors and specialized producers

- Food cooperatives, farmer groups

- Importers and exporters and global traders

- Food safety, certification & compliance bodies

- Food R&D labs and research institutes

1. Food and beverage manufacturers

ERP software for food industry manufacturers can assist with recipe management, batch production, ingredient management, and safety requirements. These companies manage complex workflows on a daily basis, from sourcing raw materials to final packaging. With ERP, they can control formulations, keep consistent quality, track every ingredient, and keep production in line with demand.

2. Food distributers and wholesalers

Distributors use ERP to manage their supply networks without delay or stocking issues. Since they transport products from factories to retailers, they require real-time visibility into inventory, truck routes, order status and warehouse flow. ERP software for food industry distribution provides tools to manage food shipments, optimize logistics, and minimize losses. It also ensures that financial data is in sync throughout the entire operation.

3. Food Retailers and Grocery Operators

Supermarkets, convenience stores, specialty shops and online grocery platforms all require accurate demand forecasting and tight pricing control, and up-to-date stock information. ERP software for food industry retail helps track the movement of products and handle shelf life. It also facilitates price changes, promotions, and enhances service with tools like POS integration and loyalty tracking. It prevents fast-moving stock from slipping through the cracks.

4. Food service brands

Restaurants, cafes, catering companies, and institutional kitchens rely on a consistent flow of ingredients and strict control over costs. ERP software for food industry operations is vital as it enhances efficiency, reduces waste, and improves planning for growing food businesses. Some systems also allow for reservations, online ordering or mobile payments, making both the staff workflow and customer experience smoother.

5. Producers of processors and special producers

Fruit and vegetable processors, meat and poultry factories, beverage lines, organic brands, artisanal makers and gourmet producers all benefit from ERP due to the detailed production requirements. ERP software for food industry processing assists in controlling lot tracking, batch controls, labeling rules, seasonal changes in supply, and quality assurance. These tools are useful to small batch creators as well as large plants, ensuring that products are consistent and completely traceable.

6. Food cooperatives, farmer groups

Co-ops and farmer organizations frequently organize several suppliers and common resources. ERP software for food industry cooperatives has collective procurement, stock management, sale tracking and originality documentation. It also maintains transparency and alignment in member operations, which is extremely important in groups that are focused on sustainability and fair production.

7. Importers and exporters and global traders

Businesses transporting food products on a cross-border basis are confronted with customs regulations, international documentation and lengthy supply chains. ERP software for food industry boosts efficiency, cuts costs, and streamlines operations, ensuring better inventory management, production coordination, and compliance with safety regulations. This decreases delays while preserving the integrity of the product over long distance routes.

8. Food safety, certification & compliance bodies

ERP software for the food industry boosts efficiency, reduces waste, and enhances planning, helping businesses manage inventory, production, compliance, and customer experience effectively. This centralizes their work and better oversees the companies they manage.

9. Food R&D labs and research institutes

Labs working on the formulation of new products or trying to improve current formulations depend on data-intensive workflows. Food companies must adhere to strict regulations in all their processes, and ERP software for food industry helps support these compliance standards. It maintains consistency in research and makes it easier to work together across research teams.

V. Final thoughts

In an industry where accuracy and reliability are crucial to long-term stability, better control of operations becomes paramount for achieving sustainable growth. ERP software for food industry operations helps support this shift by providing a clearer and firmer basis for decision-making on a day-to-day basis.

At Adamo Software, we are a leading custom software partner with global experience in building scalable enterprise and ERP solutions. Our food and beverage software development leverages emerging technologies, including AI and cloud, to deliver real operational impact.

Having delivered over 200 projects and earned a spot among Vietnam’s top digital transformation providers, we bring proven expertise to every engagement. We partner with food and beverage companies to deploy systems designed around their specific needs and growth goals.

Contact us to discuss your ERP road map today.

FAQs

1. What are the operational risks that I am actually trying to reduce?

When selecting ERP software for food industry operations, don’t be misled into following long feature lists. Instead, think about the real problems you need to fix. Some businesses are attempting to reduce spoilage in cold chain logistics. Others wish to increase the accuracy of production or avoid fines associated with mislabeled batches. Your priorities should determine the system that you choose.

2. How much accuracy of planning do my operations need?

In the food and beverage world, planning precision has an impact on everything from freshness to fill rates to profit margins. If you are dealing with hundreds of short-life SKUs in different channels, your ERP’s forecasting tools need to plan at the SKU-location-channel level. And if you have some private-label and branded production going on, the system has to have flexible forecasting models. It also needs support for variable batch sizes to match your mix

3. How much scale do I need to scale or integrate in the future?

Your ERP software for food industry growth should grow with you. The right system can accommodate new markets, brands, partners or channels without requiring a painful rebuild. A bakery expanding across regions may require multi-entity capabilities or local interfaces. A beverage company launching new products across multiple platforms may need AI-driven planning tools that will integrate seamlessly with the sales, marketing, and fulfillment platforms.

4. What are the expected returns of a mid-sized food company from a Food ERP in terms of margins, waste control, service levels and recall readiness?

A good food ERP should bring about improvements in all four. For margins, detailed costing, yield tracking and lot-level inventory, you can get a sense of which products and customers are actually turning a profit. For wastage, in-built expiration controls, FEFO/FIFO logic, smarter scheduling minimize spoilage and rework.

For service levels, real-time visibility into stock and production is used to support accurate promise dates and reliable performance of delivery. And for recall readiness, modern systems provide full forward and backward traceability. They should also include automated recall workflows to help teams identify affected materials and generate documentation in minutes.